Historical background

1876

Two Germans Lasser Neumann and Kurt Sharrar founded a confectionery factory in the old town Klaipeda and named it as "Lascha" due to the first letters of their names. The factory had the inscription "Chocolate and candy factory", although at that time it produced not only chocolates and candies, but also lemonade, vinegar, and even candles.

1945

Restoration of the factory after the devastation of the World War II and its nationalization, the new name of the factory – The First May factory.

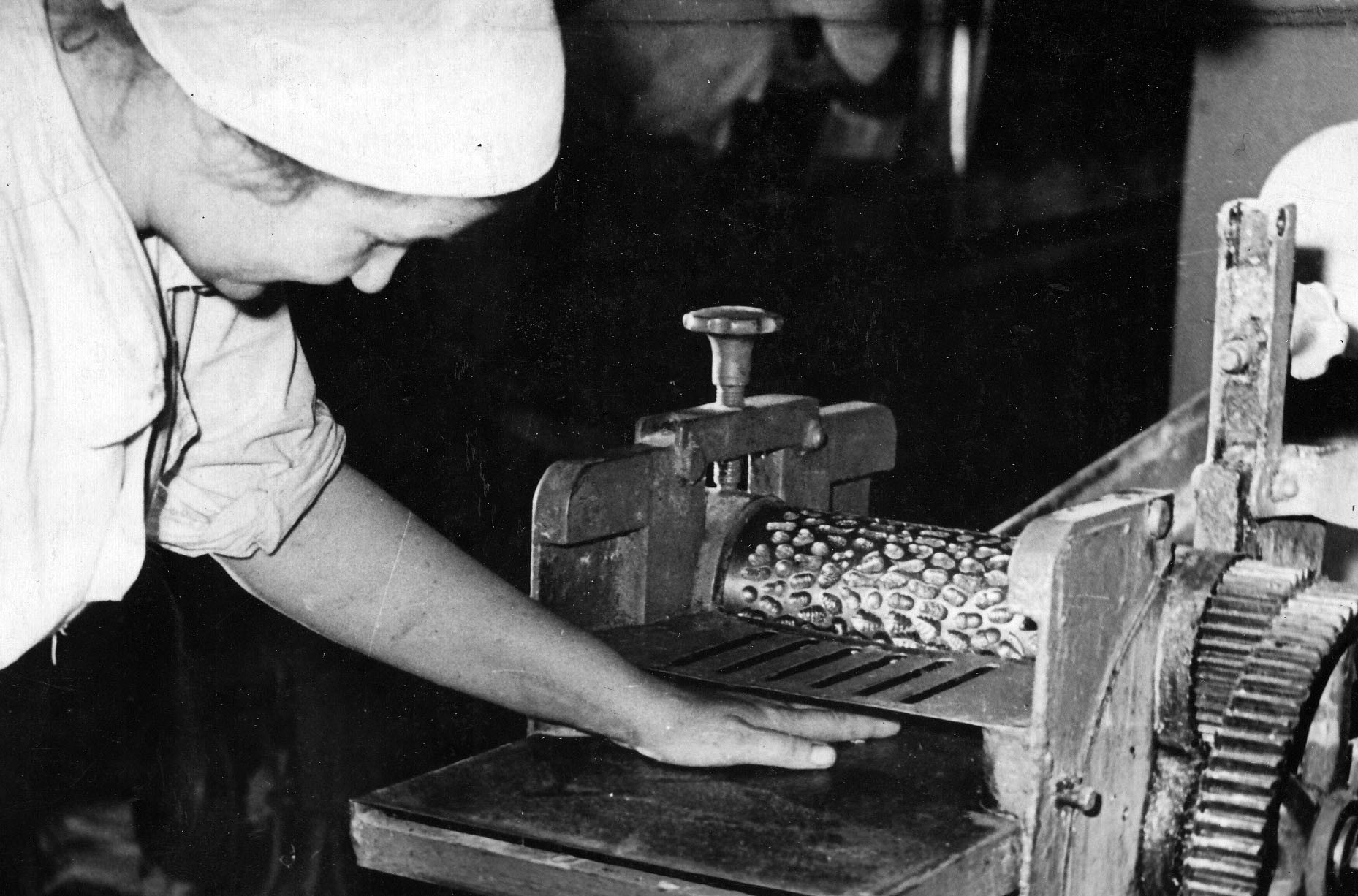

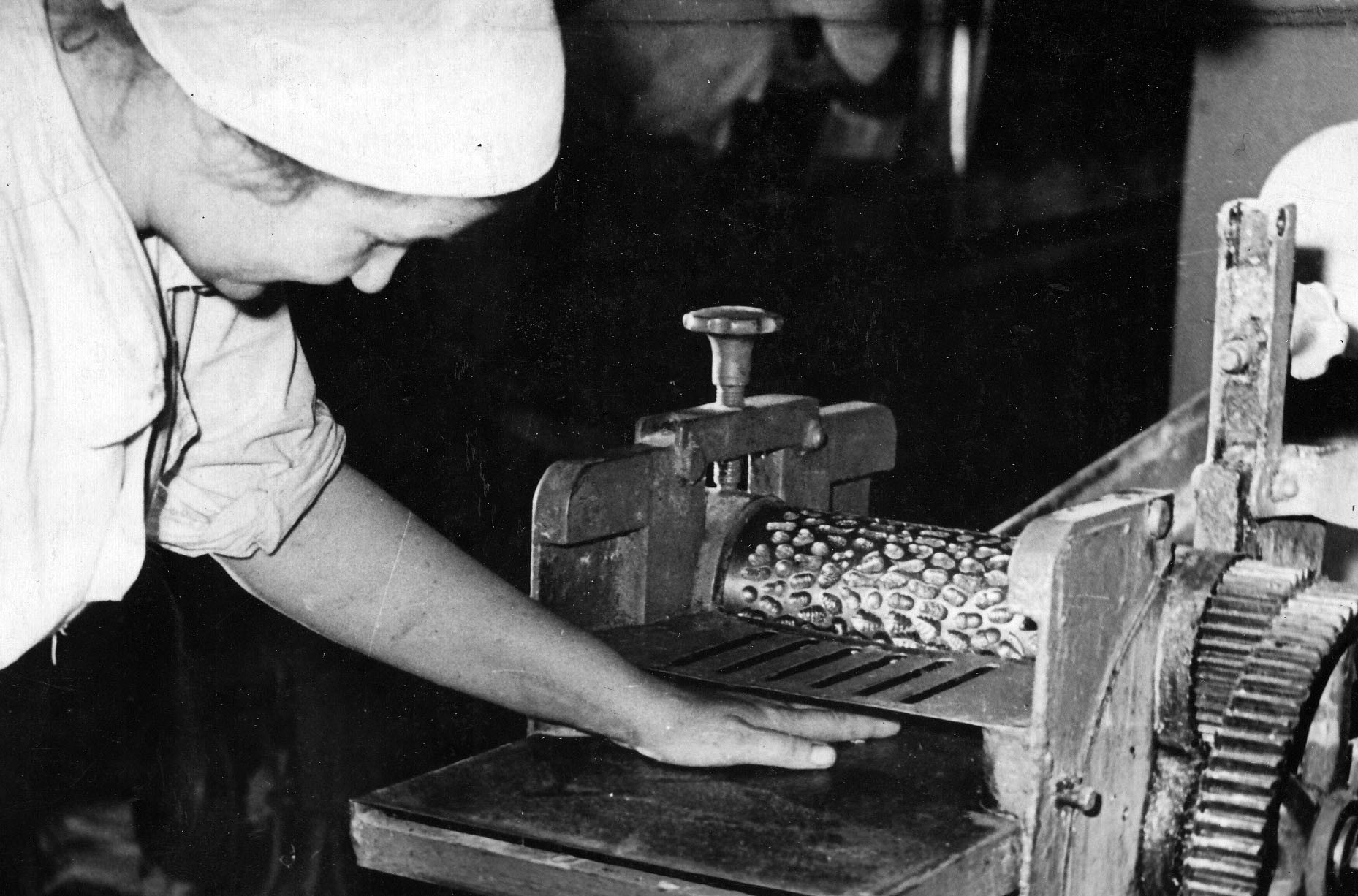

1945 - 1949

The products were produced by hand in the large copper kettles, named stove burners, which were heated with coal. The hot caramel was poured into molds, and after cooling it was manually wrapped in the labels. Only 20% of the total production was wrapped up, while the rest was just covered with sugar and sold like this. In the postwar period there was not enough raw material, so for the filling they used rhubarb, beets, and gooseberries. There were some difficulties with the delivery of the raw material: it took an entire week to get from Vilnius to Klaipeda.

1949

The beginning of the modernization of the production, the equipment for automating the manual work was installed at the factory.

1990

The production was privatized and renamed to "Klaipeda confectionery factory".

2003

The factory was certified according to the quality management system ISO 9001.

2005

The relocation from the old part of the city to the premises of the former meat factory at the outskirts of the city.

2006

The ROSHEN Corporation bought the Klaipeda Confectionery Factory.

2007

The modernization of the factory worth 750 000 euro was conducted

2007 - 2010

The volume of the Klaipeda Factory production increased from 80 up to 300 tons per month.

June 2010

The factory changed its status from AT (stock company) to ZAT (private limited company) and obtained a new name UAB "ROSHEN".

2010

The first stage of the ROSHEN Confectionery Factory’s investment in Klaipeda made up to 3.2 million euro. The total investment of 8 million euro was used for the purchasing and installation of the new powerful lines for the production of caramel products, and for increasing the efficiency of the energy sector of a factory.

2011

Completion of the modernization of the factory, after which its production capacity increased up to 1290 tons of products per month. The products of the Lithuanian factory were placed on the shelves of the EU.

2014

The Klaipeda Factory obtained the international standard of the food safety IFS 6 v.

Nowadays

As a member of ROSHEN, the Klaipeda Confectionery Factory became the first production site of the Corporation on the territory of the EU. The manufacture conforms to all international quality standards, which is confirmed by appropriate certificates ISO 9001:2008 and IFS 6 v. Now the factory has 120 employees.

ROSHEN Corporation has expanded its educational programs and on April 1, 2015, has launched the project at Klaipeda Confectionery Factory in Lithuania. Within the program children become acquainted with the history of the Klaipeda Factory, which has been manufacturing confectionery products for over 100 years, and its current areas of specialization. Also, they learn about the profession of confectioner and other professions of the industry and gain knowledge about the history and technology of confectionery production. This project stands out with its uniqueness because at the factory children can try themselves in the role of a caramel chief and make a candy by their own hands during the caramel master class. After the excursion and master class, children traditionally receive sweet gifts from ROSHEN.

The Lithuanian Association of Commerce repeatedly honors the Klaipeda Confectionery Factory with the awards:

- "The most popular caramel of 2013 Sweet Drops" (2013)

- "The most popular jelly sweets of 2015 Jelly" (2015)

- "The most socially responsible supplier" (2015)

Since 2015 the company has been owned by a socially responsible business organization LAVA. The Klaipeda Factory rationally uses the energy resources: controls the consumption, monitors the factors of the heat releasing into the environment. A great attention is paid to the sorting and recycling of the waste products. Since 2017 the company uses the green electricity.

Vinnytsia Dairy Plant

The main supplier of raw milk for ROSHEN confectionary factories delivers its products to the countries of the European Union.

Details

Kremenchuk Factory

Kremenchuk Confectionery Factory is one of the oldest enterprises in Ukraine which produces sweets. The factory specializes in making caramel.

Details